We have gravity casting, shot blasting, heat treatment & water quenching facilities. With 20 years of experiences, we are able to produce Al cast products with tight tolerances, special requirement on mechanical properties such as tensile, hardness and elongation as well as high requirement on porosity control for safety components such as automotive braking components. All our mould are the joined development effort from our design team and contracted mould manufacturer.

We have in house design team who are capable to make full range of design from cutting tools, jigs and fixture as well as manufacturing processes. All our machines are CNC programmable machines and able to provide high precision machining and consistent quality to customers. We have CNC machining centre to provide services for the following required processes:

Drilling & Tap

Boring & Honing

Milling

Turning

Electro Chemical Deburring

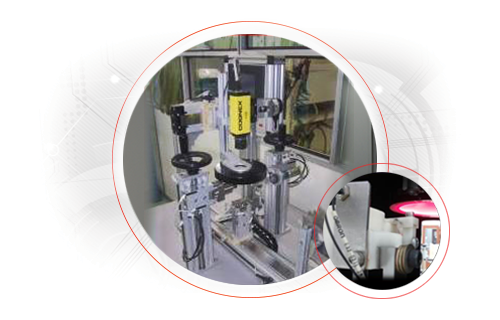

With a range of advance assembly and testing equipment including on line computerized inspection & testing. Sanyco Grand is able to conduct 100% functional testing of all brake cylinders, clutch cylinders, proportioning valves and wheel cylinders before delivery to customers. The lines are also equipped with idiot proof (Poka-yoke) concept to prevent defect produced from the line. A set up of clean room control process and facilities also enable us to produced critical safety components that meet customer requirement.